John Hollis Bankhead Lock and Dam

Johnson Machine Works was awarded the contract for the replacement of two (2) miter gate leaves for Bankhead Lock and Dam by Herry Pepper and Associates of Jacksonville, FL, on April 25, 2002. Work was completed in August of 2004.

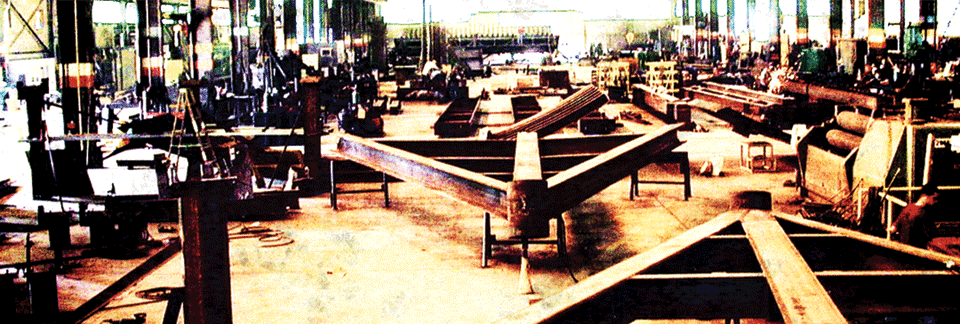

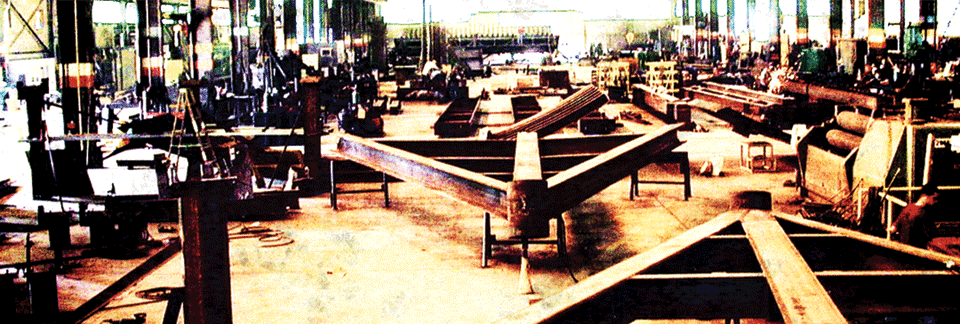

The project was for the fabrication of a miter gate to replace an existing gate that had been damaged.

Beyond the normal scope of detailing, fabrication, painting, and delivery we also provided engineering and fabrication of new lifting plates, barge platform design, and barge cradle used during the lifting/setting process.

The gate leaves were approximately 89’ tall and 62’ wide. The project called for complicated fabrication during sub-assembly as well as fnal assembly of the gates. Precision machining work was required on all contact blocks, pintle ball components, and miter gate anchorages.

Along with the receipt of a safety award as well as a letter of commendationfrom the Mobile District Corp, Johnson Machine Works also developed a patent associated with a redesign of the thrust plate assembly. The Patent No. US 7,037,039 B1 was awarded on May 2nd, 2006.

more